As a homeowner, staying informed about your electrical system is vital. Aluminum wiring was a common choice for homes built in the 1960s and 1970s because of its unique characteristics. It was initially popular for its affordability and availability but was later found to come with specific risks.

Since knowledge is power when it comes to electrical safety, this post will make sure you leave knowing the essentials. Knowing aluminum wiring, from its potential risks to identification and maintenance, you can ensure your home stays safe and efficient.

The Background of Aluminum Wiring

In the 1960s, aluminum wiring started gaining traction as an alternative to copper because it was affordable and readily available. As copper prices soared, more builders turned to aluminum as the solution for electrical wiring in homes. Lightweight and easy to work with, it seemed like a great choice at the time!

However, as the years went by, homeowners and electricians started noticing some issues. By the late ’70s, these safety concerns led to changes in building codes, and the usage declined significantly.

Homes with aluminum wiring today are often seen as having potential safety hazards. As a homeowner, it’s essential to be aware of these risks and consider upgrading or retrofitting your wiring to meet modern safety standards.

Benefits and Risks of Aluminum Wiring

It’s often thought to have solely negative traits, but was a popular choice at one time for several compelling reasons.

- Aluminum provided a much cheaper alternative to copper for wiring homes, making it a budget-friendly option for builders.

- The material is significantly lighter than copper, which makes it easier and quicker to install, reducing labor costs and effort.

- Despite being cheaper, aluminum still offered good electrical conductivity, ensuring homes had a reliable power supply.

The Risks

Conversely, it introduced several risks that homeowners need to be aware of.

- Unlike copper, aluminum expands and contracts more with temperature changes. This can cause connections to become loose over time, leading to overheating and increasing the risk of electrical fires.

- Aluminum is prone to oxidation, which creates a layer of corrosion on the wire’s surface. Corrosion increases electrical resistance and can cause overheating, posing a significant fire hazard.

- This metal is more brittle than copper and can break more easily, especially at connection points. This brittleness can result in poor connections, increasing the risk of overheating and fires.

- Aluminum wiring requires special connectors and techniques to ensure safe connections. Using standard connectors designed for copper can lead to dangerous situations, including overheating and electrical fires.

Identifying Aluminum Wiring

Knowing how to identify aluminum wiring in your home is how you maintain electrical safety! First, consider your house’s age – homes built between the mid-1960s and late 1970s are more likely to have it. If your home falls into this category, it’s worth investigating further.

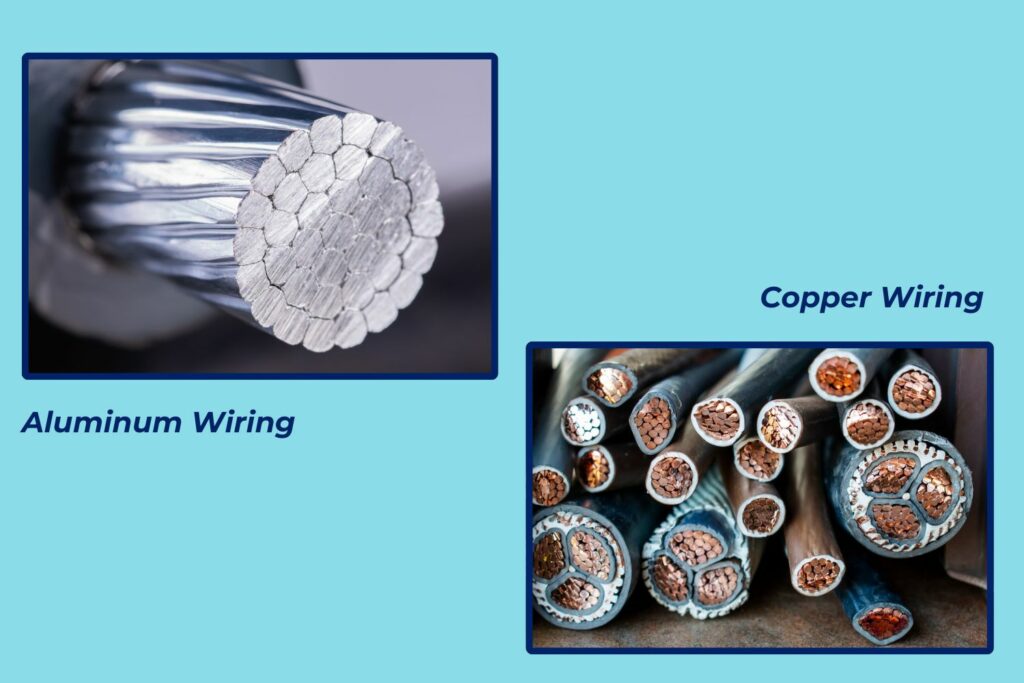

Then, inspect your electrical panel. Look for any labels or markings that indicate the type of wiring. Aluminum wires are often marked with “AL” or “ALUMINUM.” Also, inspect wiring wherever it’s visible, such as basements or attics – look for silver-colored wires. Copper wires will have a reddish-brown color, while aluminum wires are distinctly silver.

Finally, check connections for outlets and switches. Carefully remove the cover plates from outlets and switches to inspect the wires connected to the terminals. As we touched on above, aluminum wiring will appear silver. Make sure you turn off the power beforehand to avoid any electrical hazards.

Safety and Maintenance Tips

Maintaining safe aluminum wiring in your home is possible, but it does require regular care and attention.

1) Regular Inspections

Schedule periodic inspections by a licensed electrician. These inspections can help identify loose connections, signs of corrosion, and other potential issues before they become serious hazards.

2) Use Proper Connectors

Ensure that any repairs or modifications are done using connectors specifically designed for aluminum. Using common connectors for copper wiring can lead to dangerous overheating when used with aluminum.

3) Avoid Overloading Circuits

Be mindful not to overload circuits connected to aluminum wiring. Overloading can cause the wires to overheat, increasing the risk of fire.

4) Check for Warm Outlets and Switches

Regularly feel your outlets and switches for warmth. Warmth can indicate a poor connection or an overloaded circuit, which requires immediate attention.

5) Replace Damaged Wiring

If any aluminum wiring appears damaged or frayed, have it replaced immediately by a professional to prevent potential safety hazards.

Legal Considerations

First things first, you should familiarize yourself with local building codes and regulations regarding aluminum wiring. Some areas may have specific requirements for inspections, upgrades, or replacement.

Disclosures and Insurance

Also, notify your insurer if your home has aluminum wiring. Many insurance companies view aluminum wiring as a potential risk and may require an inspection or specific upgrades to maintain coverage.

Similarly, if you plan to sell your home, you may need to disclose the presence of aluminum wiring to potential buyers.

Retrofitting and Upgrades

Finally, investing in retrofitting or upgrading your wiring to meet modern safety standards can improve safety, potentially lower your insurance premiums, and increase your home’s value.

When to Call a Professional

You can take some maintenance steps independently, but sometimes an expert’s eyes may be necessary. For instance, if you notice flickering lights, warm outlets or switches, or strange odors near electrical panels or outlets, call a professional immediately. These are signs of serious issues that need prompt attention.

Even without apparent issues, it’s wise to schedule regular inspections by a licensed electrician. They can identify potential problems like loose connections or corrosion before they become hazardous.

When considering upgrading or retrofitting your aluminum wiring, always hire a professional. They’ll get the job done safely and comply with current building codes and standards. For any major electrical work, such as adding circuits or installing heavy appliances, a professional should also handle the job.

Conclusion

Hopefully, this post was able to provide you with answers or peace of mind. To summarize, while aluminum wiring undeniably comes with certain risks and special care, it is possible to keep your home safe without an electrical overhaul.

If you have questions about your home’s electrical system or need to schedule a complete inspection, call Boggs Inspection Services in Olympia, WA, and surrounding areas.